For about 20,000 years people have been making their clothes by sewing. Internationally, clothing is still produced by sewing or gluing, the use of 3D printing currently leads to very unfavorable wearing properties due to the material and is not economical, especially because of the relatively slow working method.

Sewn textiles are now being produced all over the world with modern sewing machines and the first sewing robots, although the actual process for manufacturing the clothing has hardly changed. The production of clothing still requires many work steps: from the production of the materials (textile fabrics, leather, plastics) to cutting and sewing to the attachment of fasteners and accessories.

Even with optimized processes, around 10% of the materials are wasted during the manufacturing process, which cannot be reused, which also applies to gluing.

This leads to a high production cost and corresponding price and price pressure. Many textiles are currently being produced in Asian countries under sometimes environmentally destructive and disastrous occupational safety conditions and are repeatedly criticized.

It can also be seen that due to the different fiber materials and coatings, there is currently almost no real recycling (used clothing to make new clothing).

For these reasons, the international innovation network has set itself the goal of developing materials, processes and a complex system for the production of functional clothing with integrated technical functions - almost entirely using the spraying process, using the example of protective motorcycle clothing.

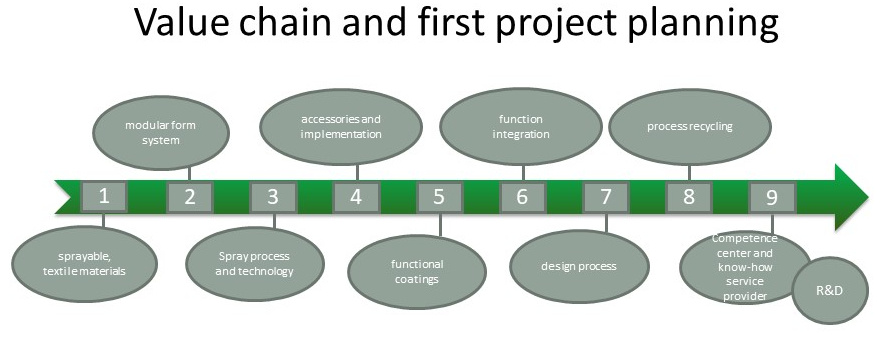

A complete value-added chain is to be set up, from the manufacture of materials and the production of textiles to marketing and recycling processes. The focus of the developments is that as many work steps as possible are carried out using spray processes, and thus as quickly and efficiently as possible.

Goals to be achieved are:

- Very fast and inexpensive production of garments (jackets, trousers) in just a few work steps and without seams,

- Use of recyclable materials to recycle production waste and obsolete or damaged clothing,

- new design variety (also surface structure),

- Implementation of components (e.g. sensors, heating, protective elements, ...) in the material during the manufacturing (spray) process of the clothing,

- Production according to European standards.

Furthermore, the network is to be further developed into a competence center and know-how service provider (as a basis for the provision and further development of technological competence).